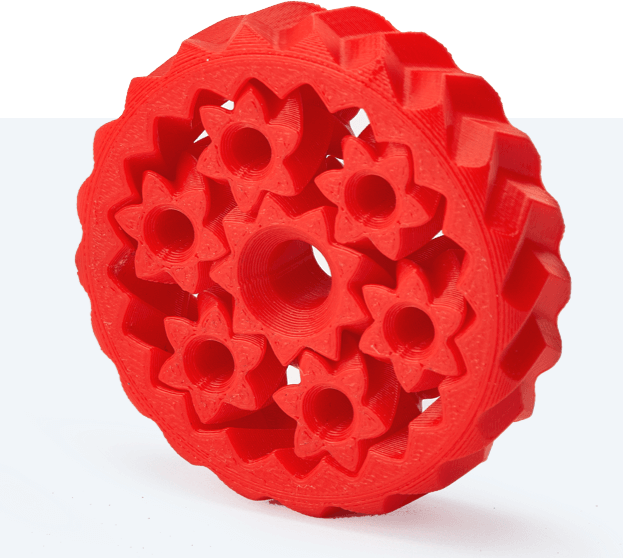

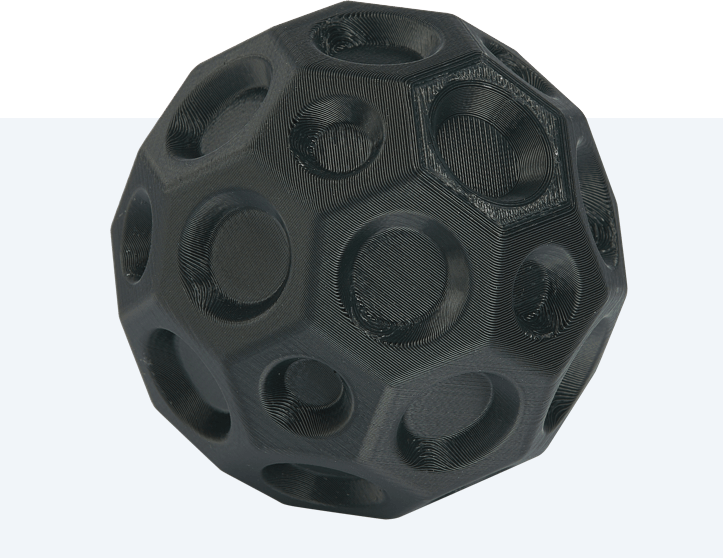

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM), a commonly-used 3D printing technology, is renowned for its versatility in creating prototypes layer-by-layer, production parts, and cost-effective solutions.

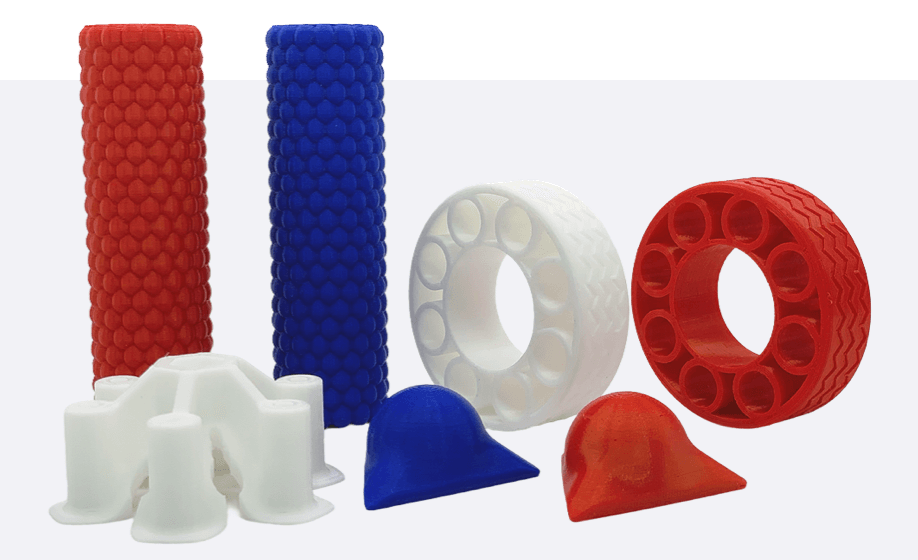

We pride ourselves on utilising high-quality materials. While our default choice is PLA+, an eco-friendly plastic derived from renewable plant sources, we understand that different projects require different materials. This is why we offer a wide variety of options to suit your needs.

PLA

PLA (polylactic acid) is the most used filament in 3D printing. Unlike ABS, it is biodegradable (made from corn starch), so it can be used to print objects that will be in contact with food products (plates, bowls).

It is increasingly used in the food industry to pack products such as fruits, vegetables, eggs, but also to replace tote bags and plastic bags distributed so far in the shops. On the other hand, it is quite sensitive to heat and water.

PLA is one of the easiest materials to print, its main feature being its low shrinkage, which does not necessarily require having a hot plate on the printer.

If it responds well to post-print processing like painting, it’s pretty hard to make it perfectly smooth. Indeed, the heat of friction of the sanding paper tends to melt the material.

There is a wide variety of colors that will allow you to give free rein to your imagination.

ABS

ABS (Acrylonitrile Butadiene Styrene) is the most used material in the industry. Indeed, a large number of parts for automobile, electronics and appliances are made from this material. This is also the case for Lego bricks.

It belongs to the family of thermal plastics (or thermoplastics) and therefore has a base of elastomers that makes it more flexible and resistant to shocks. In addition, it supports temperatures between -20 ° C and 80 ° C.

In addition to its excellent strength, ABS is reusable, perhaps polished or welded by chemical processes (using acetone). All these technical features make it the preferred material for engineers.

It’s derivative, ASA, is more suited for outdoors use in direct sunlight and high UV light environments

PETG

PET (polyethylene terephthalate) is even stronger than ABS. It is mainly used for the manufacture of parts requiring both flexibility and robustness.

It is the ideal material for parts intended to be in contact with food products. It is found for example in plastic bottles or in plastic glasses found in events such as festivals or concerts. In addition, PET is 100% recyclable.

There is a variant that is PETG (polyethylene terephthalate glycolized). The only difference is that the PET is brittle while the PETG is more flexible and therefore breaks less easily.